Upstream Gas Gathering/Wellhead

Today natural gas accounts for 23% of the world’s energy consumption and usage is growing. Getting this abundant, environmentally friendly fuel into the global energy stream requires compressing it for efficient handling.

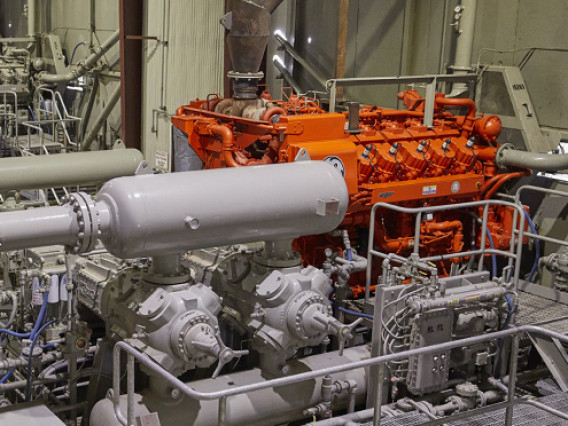

Engine-driven compressors compress gas at the wellhead, gather gas from multiple wells, and send it to processing facilities. INNIO’s Waukesha* gas engines are designed for this demanding application. INNIO's Waukesha gas engines are backed by more than a century of engine building expertise.

How it works?

At the wellhead, engine-driven compressors manage the flow of gas from the well and into the pipeline.

With a higher-pressure well, well pressure works with the suction function of the compressor to aid the compression process.

At low well pressures, the compressor draws gas from the well into the compressor. The compressor boosts gas pressure to a level slightly above pipeline pressure so gas flows into the pipeline.

Gas gathered from multiple wells is compressed by engine-driven compressors and sent through a central pipeline to a designated location.

In coal seam and unconventional gas evacuation, the compressor, operating at very low suction pressure, extracts gas from a coal zone for processing and sale, or to make the area safe for mining.

For wellhead and gas-gathering applications, a dependable engine-driven compression system that operates efficiently is essential to keeping the gas moving and productivity and profitability high.

INNIO’s portfolio of Waukesha gas engines for compression applications offers multiple options to address individual site conditions and widely varying local emissions requirements.

Features & Benefits

- Durable: Running on raw gas from the wellhead, INNIO's Waukesha gas engines perform with extreme reliability in remote and often harsh environments.

- Fuel tolerance: Waukesha gas engines can handle significant variations in field gas quality and keep on running. More uptime means more profit.

- Greater productivity: Waukesha gas engines run at full power at higher altitudes and higher ambient temperatures, compressing more gas for more profit.

- Emissions flexibility: INNIO offers technology options to meet most local air quality mandates.

- Lower emissions per horsepower: Rich-burn Waukesha gas engines with 3-way-catalyst enable more horsepower per site for more productivity and profit.

- Total engine control: INNIO’s Waukesha ESM* fully integrated control and diagnostics system optimizes engine performance and maximizes uptime.