myPlant APM Solution

DIGITAL ENGINE TECHNOLOGIES WORKING SMARTER FOR YOU

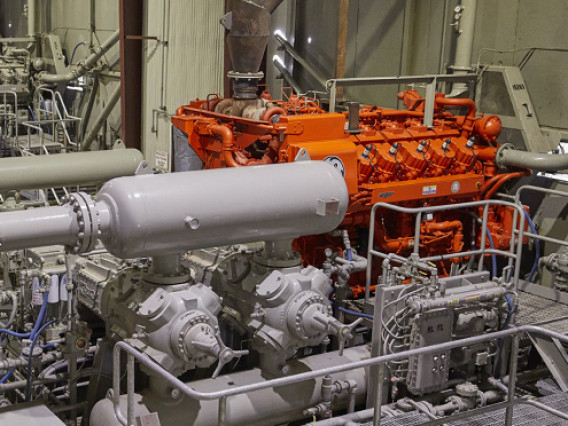

INNIO Waukesha's myPlant APM solution provides preventative and predictive analytics for engines, compressors, and oilfield equipment. This cloud-based technology lets you manage your assets wherever you are in a secure and live setting.

BUILT TO WORK SMARTER. YOUR POWER. YOUR DATA.

IN YOUR HANDS.

Take a closer look at how our myPlant solution can support your operational profit drivers. They include:

Why is security so important to us? Because it’s important to you.

Read more about myPlant cybersecurity policies that keep your operations secure.

What our customers say

“With our fleet spanning over a 100-mile remote footprint, we were in need of a solution to troubleshoot and avoid package downtime. The Waukesha myPlant system allows my crews to efficiently monitor and solve issues remotely using the iPhone app. With myPlant we’re able to monitor engine operations and identify issues before they become shutdowns. This provides us optimized maintenance, increased revenue, and higher operating hours.

Michael Jury, Sr. Maintenance Foreman - HighPoint Resources - Powder River Basin

Our myPlant APM solution gives you the right information at the right time for your entire engine fleet

Explore myPlant’s powerful features and see how.

Comprehensive asset dashboard

Say goodbye to scattered data sources. Get an extensive overview on your operations at a glance.

- See your engine’s and site’s operational and performance data during your selected period.

- View engine and component status, start success rate, operating hours, number of shutdowns and engine alarms.

- Customize the dashboard for your specific needs by trending four different engine elements of your choice.

- No need to waste time searching: find the latest support cases and all relevant engine documents on the same dashboard!

Detailed Fleet Reporting

Provides valuable insights via a simple fleet overview

- Deeper data exploration through individual reports for all connected assets.

- Includes alarms, performance, and other operational data.

Impactful predictive analytics

Don’t guess: Know it before it happens. Let myPlant algorithms do their work and notify you so that you can take preventive action.

- myPlant algorithms continuously analyze the data streamed from your assets to detect any deviations that could cause unplanned events.

- Based on the data from thousands of engines, analytics algorithms distinguish patterns of healthy engine operations—and note when deviations occur.

- When relevant deviations are detected—and before any unplanned events have occurred— you are notified immediately via email or SMS and receive recommendations on what to do.

- Analytics algorithms also provide accurate lifetime predictions for engine spark plugs, lubricants and filters—so you replace them only when necessary.

Key customized notifications

Adapt myPlant to your needs and receive notifications as you need them

- Manage notifications from a centralized location.

- Easily create new notifications.

- Choose from three different notification categories: engine status, rule-based or emissions.

- With engine status-based notifications, receive notifications based on engine analytics, start/stop and tripped status updates, for example.

- With rule-based notifications, customize your own metrics (for instance, when gas temperature decreases to x° C) and receive notifications on those metrics.

- For emissions notifications, learn when set emissions levels are exceeded.

Secure remote visibility

Access your engine—and resolve your event—remotely.

- Access and operate your engine as if you were standing in front of your engine controller.

- Adjust engine parameters according to your needs.

- Know that access to your engine controller is protected with multiple security measures.

Data trending

Plot historical data with a diagnostic workbench to quickly resolve engine events. Combine it with our secure remote connection for even better results.

- Simultaneously explore and compare data trends of multiple engines and data items.

- Choose your favorite assets and data items to optimize your workflow.

- Review data items against engine alarms to find correlations.

- Download graphs in multiple formats (JPG, CSV, XLS) and share your findings with your team.

Reporting and data consolidation

Get valuable fleet-level insights through myPlant’s automated reports.

- Get insights on fleet operations, connectivity, maintenance and performance to stay on top of key topics.

- Drive operational savings by automating your reporting processes.

- Integrate oil and coolant reports from laboratories to store all necessary data in myPlant.

WAUKESHA myPLANT DIGITAL SERVICES:

|

Offering |

Connect |

Protect |

Value |

|---|---|---|---|

|

24x7 real-time continuous data availability |

✔ |

✔ |

Ability for analyst, operators, management, etc. to access up-to-date data remotely, anytime |

|

Exception-based updates |

✔ |

✔ |

Data is continuous but myPlant updates only when there is a change |

|

Alarm management with email and SMS notifications |

✔ |

✔ |

Set up warnings/alarms on any data point and receive real-time notifications. |

|

Mobile applications |

✔ |

✔ |

Mobile application access on real-time data from anywhere in the world. |

|

Fleet and Asset-level KPIs |

✔ |

✔ |

Monitor fleet and asset-level key performance indicators (KPIs) for quick health checks. |

|

Historic and live data trending |

✔ |

✔ |

Historical and live trending capability of any data point for monitoring and analysis. |

|

Live asset operating status |

✔ |

✔ |

Ability to view real-time fleet operating status for pipeline management. |

|

Extended hardware warranty |

✔ |

✔ |

Extended warranty for APM hardware. Free replacement of parts with active subscription. |

|

Engine Balance Reports |

✔ |

✔ |

Quickly scope out the engine balance across both banks for issues. |

|

Oil and coolant quality monitoring |

✔ |

Ability to integrate third-party oil and coolant analysis services. |

|

|

Advanced compressor and engine analytics |

|

✔ |

Advanced compressor and engine analytics developed by OEM and industry experts |

|

Compressor leak detection model |

|

✔ |

Compressor leak detection access. Leaks make up approximately 75% of compressor issues. |

|

Remote support |

|

✔ |

Remote support of compressor and engine issues with recommendations. |

|

Monthly Price/Asset |

$40.00 |

$100.00 |

|

|

Annual Price/Asset |

$500.00 |

$1,200.00 |

|

|

Note: Asset includes compressor and engine or BOP equipment |

|

||

|

Note: Cellular service fees are included in the price |

|

||

Rely on our many years of engine manufacturing experience and fleet operational knowledge with more than 15,500 connected assets and 4,000 average active users:

30 billion+ minutes of connected assets

1.1 million+ monitored sensors

10 TB+ of data processed every year

70+ preventive analytics available

COMPLETE THE FORM TO GET STARTED WITH myPlant TODAY

Contact US