There are many solutions that can be considered for power generation applications. If gaseous fuel is available, many customers today are weighing the pros and cons of reciprocating gas engines, gas turbines and other gas-fired solutions. In this article, Jenbacher experts provide our thoughts on what you should consider when selecting power generation equipment.

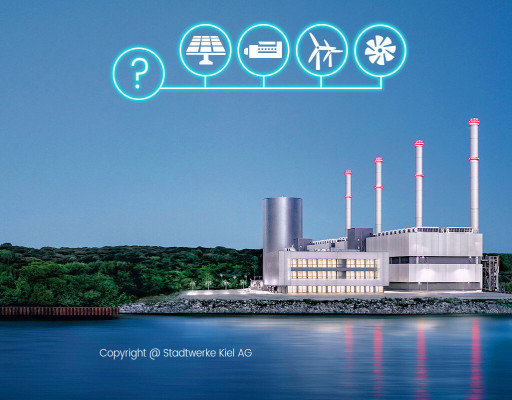

First, however, here’s a little background on reciprocating engines: They are used in a wide variety of power generation applications across different industries, from food and beverage applications that use less than 1 MW to industrial segments of up to 100 MW. And then there are even bigger projects for major utilities, such as the recently commissioned 190 MW project for the Stadtwerke Kiel in Germany. This large combined heat and power (CHP) project uses Jenbacher J920 FleXtra gas engines.

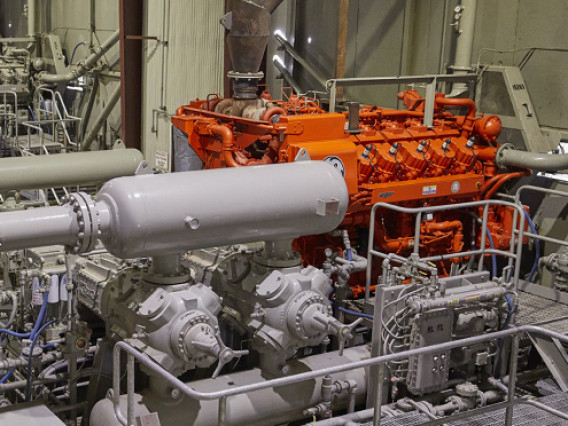

As a company that produces dependable Jenbacher* reciprocating gas engines with electrical efficiency usually ranging between 40% and 50%, we know that gas engines often can be compared with gas turbines or any other conventional power generation technology. Moreover, gas engines can work in combination with other types of equipment, renewable energy sources or battery storages, increasing the efficiency and flexibility of the overall system. Finally, gas engines are used successfully to modernize or repower current power generation infrastructure.

Important aspects to consider when selecting power generation equipment

Because we share your desire to find cost-effective, technically reliable and greener power generation solutions, we urge you to pay attention to the following factors when comparing different technologies:

Modularity and availability of ready-to-use solutions

Modularity and availability of ready-to-use solutionsWhy onsite power generation?

In addition to these factors, onsite power generation may provide you with significant benefits, such as:

- Decreased energy-related operating costs. When energy is produced at the place of its end use, costs can be lower than when energy is supplied by a third party via grid and central systems.

- Avoided energy losses due to electric power distribution from central power stations to distributed consumers.

- Avoided expensive power transmission and distribution upgrades due to increased local demand.

- Prompt access to electrical and thermal energy. This is especially important for energy-deficit regions and for locations that don’t have the ability to connect to centralized energy sources.

- Improved reliability of the electric power source for locations with unstable grid infrastructure and for facilities with increased requirements for energy supply reliability.

Contact our experts

To learn more about the potential benefits of Jenbacher gas engines for your business. Fill out the form on the right or email us at contact.en@innio.com

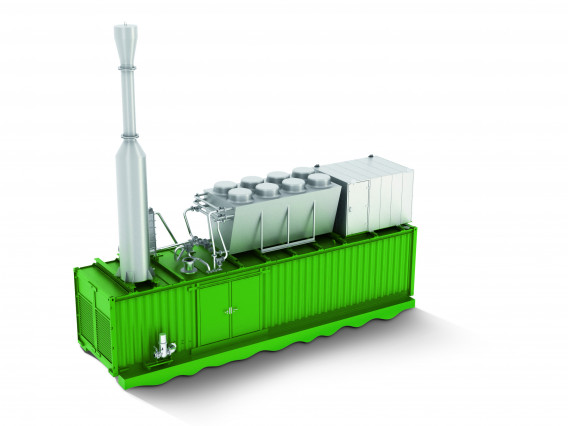

When INNIO designs our solutions, we take into account our equipment’s eventual delivery to the installation sites. Our solutions can be installed in buildings or can be packaged into easily constructed modular structures. For example:

When INNIO designs our solutions, we take into account our equipment’s eventual delivery to the installation sites. Our solutions can be installed in buildings or can be packaged into easily constructed modular structures. For example: