INCREASE POWER,

REDUCE DOWNTIME.

Waukesha gas engine upgrades are an excellent option for customers who are approaching overhaul or service events and looking to upgrade their engines to match the latest designs using genuine OEM parts for the VGF, VHP and 275GL+ engine lines.

Technology

Upgrading your existing engines with today’s advanced technologies delivers added horsepower to your equipment without increasing physical footprint while improving reliability, reducing operating costs, achieving maximum runtime and experiencing less unplanned maintenance.

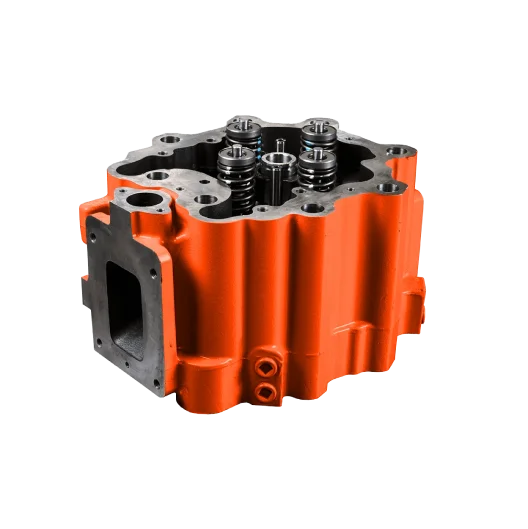

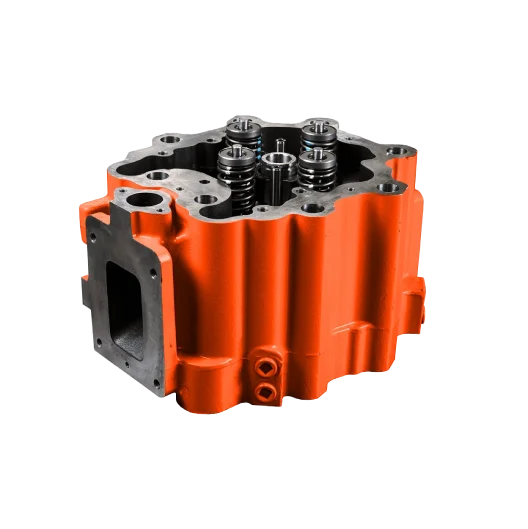

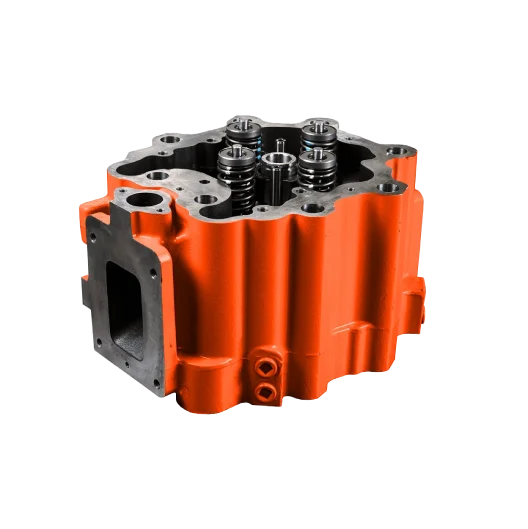

VGF Lean-Burn Cylinder Head Upgrade

- Reduced valve recession rates due to introduction of valve rotators.

- Reduced wear provided by optimized material and dimension.

- Extended top end intervals:

- Up to 50% longer intervals between top end overhauls (from 16,000 hours to 24,000 hours).

- Elimination of every third top end overhaul.

- Up to 25% savings in $/hr life cycle.

VGF GL to GSI Conversion/Upgrade

VGF GL to GSI Conversion/ Upgrade

- Operate your engine almost anywhere in the world with its decreased emissions through the use of a three-way catalyst.

- Increased fuel tolerance provides more power on hot fuels and better availability during changes in fuel quality.

- Better availability through ambient temperature changes keeps your engine running.

- More power at high altitudes with a favorable derate curve.

- Save money with improved lifecycle costs (excluding fuel).

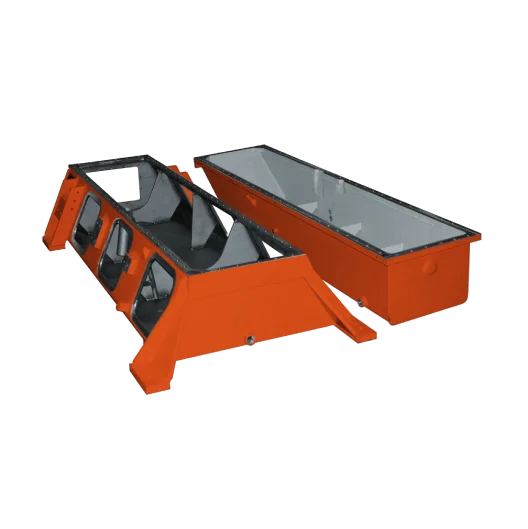

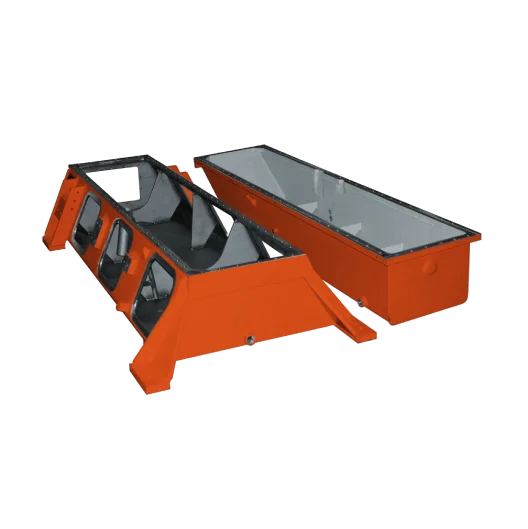

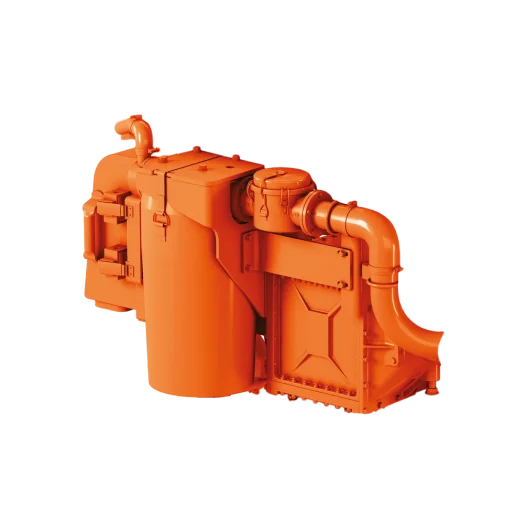

VGF High-Capacity Oil Pan Upgrade

Reduce costs and increase uptime by upgrading your VGF engine to the new high-capacity oil pan.

- Reduced maintenance costs due to 2x extended oil change intervals.

- Increase in productivity and operational flexibility with extended periods between planned maintenance.

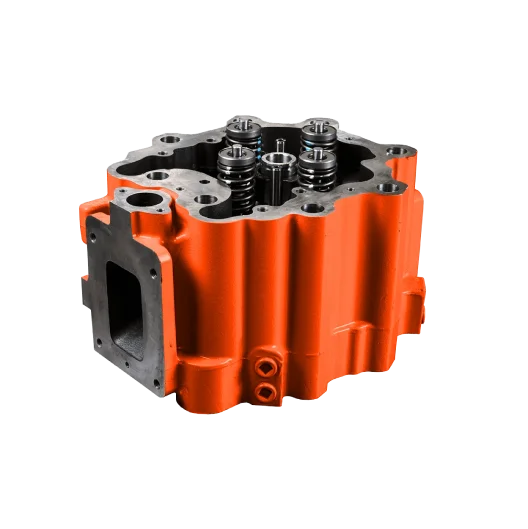

xCooled HEADS AND PISTON UPGRADES

Experience increased uptime, reliability and extended lifecycle intervals with INNIO’s VHP xCooled cylinder head upgrade.

Offering enhanced cylinder head cooling by improving the flow of coolant to critical cylinder head components, the xCooled head has shown proven field-tested results operating at sites with high LHV fuels. The xCooled cylinder head is offered as a direct replacement for existing Series Four GSI cylinder heads, aligning well with top-end and bottom-end overhauls.

- Improved reliability when operating on high BTU fuels. Enhanced cooling at the exhaust valve and guide reduces component temperatures up to 40%, lowering thermodynamic stresses in critical components.

- Extended intervals lead to more time between overhauls, which increases uptime and reduces operating cost. Up to 33% longer intervals between top-end overhauls; 32,000** hours on an L7044GSI engine operating up to 1,680 BHP @ 1,200 RPM continuously.

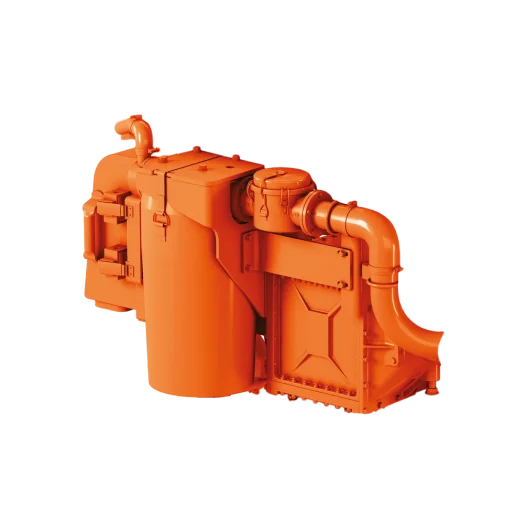

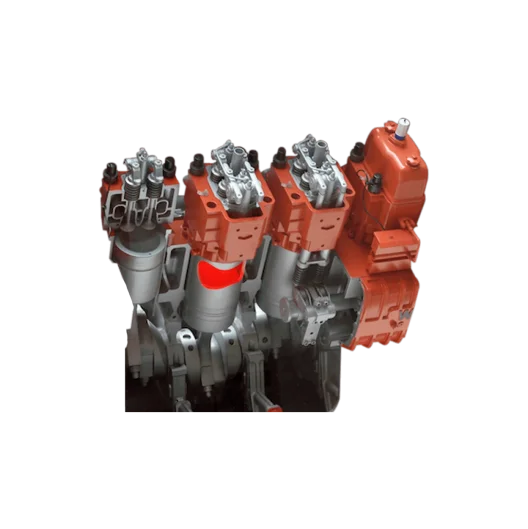

Advanced Breather

- Reduced oil blow-by. The breather separator assembly reduces oil blow-by as much as 90 percent compared to the previous system.

- Less oil contamination. The advanced breather design can help to significantly reduce oil contamination of the three-way catalyst element.

- Reduced coking. Because the breather system is connected to both turbocharger banks, the risk of coking the turbo and intake system is greatly reduced.

- Extended service intervals. While dependent on operating conditions, breather element service intervals are estimated to double to 8,000 hours.

- Fewer oil leaks. The crankcase vacuum is maintained across speed/load changes for enhanced sealing capability that results in reduced potential for crankcase oil leaks.

P9390X

Introducing the VHP 9390X 1980 bhp power rating, 900-1200 rpm, 10% overload. Upgrade kit includes xCooled heads, Series Four pistons, ESM 2/AFR2 integrated control system, advanced closed-loop breather and emPact catalyst. Available as an upgrade or reUp engine.

- Extends the life of existing equipment with modernized controls.

- Catalyst emissions control and monitoring.

- Simpler maintenance and increased reliability.

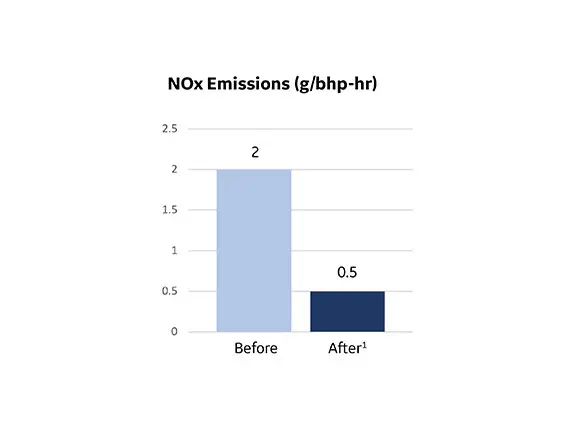

ATGL to 275GL+ Conversion Upgrades

- ESM* control provides enhanced reliability in a single system.

- Improved output to 3625HP(12V), 4835(16V) and option to further increase output by 3.5% with Power Push.

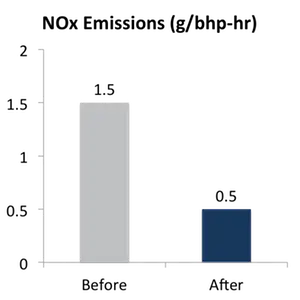

- Improved air-fuel ratio control and decreased NOx emissions to 0.5 g/hp-hr with new NOx sensor.

- Reliability improvements to wastegates, exhaust bellows, and many other systems.

The right upgrade for your engine.

For questions about our upgrades or for any assistance you may need in selecting the best one for your equipment, please contact us.